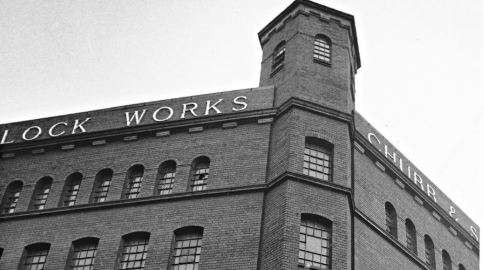

Chubb

Posted Friday, January 18, 2019 by Chris Leggett under

The brothers Charles and Jeremiah Chubb were born in Hampshire in the late 1700s, writes Molly Forsyth.

Both brothers became blacksmith apprentices, with Charles starting out as a ships’ ironmonger in Winchester before moving to the dockland area of Portsmouth in 1804, and Jeremiah soon joining him.

In an area rife with crime, Jeremiah Chubb patented a “detector lock” in February 1818. Picking attempts or use of a wrong key would trigger an in-built detector mechanism, rendering it unlockable and requiring a special key to reset it. The locks worked to deter trespassers, especially as a broken lock would alert a property owner of attempted break-ins. In 1824, the lock was improved, removing the need for the second key.

The invention marked the founding of Chubb as a company. Demand for the lock continued to grow, further helped by winning a government-commissioned contest to find the most secure lock in manufacture.

Chubb’s first known connection to the West Midlands can be dated back to an issue of the Wolverhampton Chronicle, on 10 June 1818, when a recruitment advert was placed for local locksmiths wanted by Jeremiah. Although recruits were relocated to Portsmouth, the decision by the brothers to advertise in Wolverhampton was perhaps down to realising that the future of production lay in a location at the heart of iron manufacture and chain-making.

Indeed, by 1820, Chubb had a works in Temple Street, operating until 1836 when they relocated to St. James’ Square. Business in Portsmouth was officially closed, and Chubb opened a London office to connect their operations in Wolverhampton with a larger industry link.

Putting the finishing touches to a Chubb safe at the Wednesfield site is “spaceman” Terry Platt, 1979

In 1835 Chubb had taken out a patent on a burglar-resistant safe and in 1837 opened their first safe works at Cowcross Street, close to Smithfield Market in London. From this time the manufacture of safes, vaults and safe depots assumed equal importance with that of locks. In 1838, the works relocated again to Horsley Fields and Mill Street, where they remained for over forty years until 1882, when Chubb became a limited company.

They then operated from London until returning to Wolverhampton in 1889, this time at Railway Street, in a building that could accommodate 350 locksmiths and the same number of safe makers. At their peak, they produced around 28,000 locks a year.

Chubb was expanding rapidly throughout the second half of the 19th century, as well as thriving in the export market. In 1894 they set up a subsidiary company in South Africa; in 1896 one in Australia; and they had representation in many other countries.

Members of the Chubb family remained in control of the company well into the 20th century. Charles Chubb’s youngest son John entered the business and, after Charles’ death on 16 May 1846, was the sole proprietor. On John’s death in 1872 he was succeeded by his three sons, John Charles, George Hayter and Harry Withers.

In 1909 Chubb closed their London safe works in order to concentrate production in Wolverhampton, extending their existing Wolverhampton works across a site at Wednesfield Road.

During the First World War the company turned nearly all of its works over to war production. By the end of the war, export trade picked up again, and Chubb had opened a factory in Sydney, Australia by the 1920s.

In 1938, the works were expanded further, bringing the total factory to over 6.5 acres.

Developments in lock and security devices continued, in an effort to combat the new technologies being employed by cracksmen and thieves to overcome mechanisms within older locks. In 1947, Chubb formally moved away from making handmade locks, choosing to only manufacture machine-made locks to ensure a high degree of security at affordable retail prices.

In 1956, Chubb acquired London company Hobbs Hart and Co Ltd. Further growth strategies were employed in the 1960s, including a separate site for safe deposit lockers in Park Lane, and new offices on Wednesfield Road.

With increasing overseas competition emerging throughout the 20th century, the Chubb Group also acquired Willenhall company Josiah Parkes and Sons (Holdings) Ltd and Liverpool safe makers Chatwood Milner in the 1960s, as well as Lips in Holland in 1973.

Racal’s dislike of central London offices lead to Chubbs’ head offices being moved from London to Wednesfield Road during 1985. In 1986 Racal acknowledged the strength of the Chubb name by renaming the whole group of companies Racal-Chubb Products Ltd. The steady growth of sales in the range of commercial locks, which had begun in the 1960s, continued over the next 15 to 20 years.

The Chubb & Sons Lock & Safe Co. Ltd. was taken over by Racal Electronics in 1984. Prior to the takeover Chubb had already decided to create separate Lock and Safe Divisions and these came into being in 1984 under the names Chubb Safe Equipment Co (to manufacture safes, strong rooms and fire resistant cabinets) and Chubb Lock Co. (to manufacture locks for residential and commercial markets).

By the mid 1980s, production of the specialised safe and contract locks for prisons, letter boxes and other high-security purposes was severely restricted. April 1989 saw the launch of Chubb High Security Locks Division.

In the mid 1990s, Chubb Security plc was one of the world’s largest security companies. In October 1992, the shareholders of the Racal Electronic Group approved the £650million hiving off of Chubb Security plc, a firm that employed more than 1000 people. The reasons behind this decision to float Chubb were complex but a hostile bid for Racal-Chubb in 1991 by Williams Holdings was a major factor. In April 1997, Williams Holdings finally acquired Chubb Security plc.

Williams’s policy became to import cheap safes from Indonesia, which resulted in major job losses over the next two years. In August 1999 Chubb Safe and Security Equipment Division at Wednesfield Road, Wolverhampton, employed 350 people and were reported to be looking to reduce this by 10%.

In August 2000 Williams Holdings sold Chubb Safe and the High Security Equipment Divisions, with the rest of their lock making interests, including Yale and Parkes (Union), to Assa-Abloy of Sweden. The deal was finally signed in August 2000. Assa-Abloy, having no interest in the production of safes, immediately sold the Chubb safe making division to Gunnebo, another Swedish Company, while retaining the High Security Locks side. At the time it was reported that the Safe division employed 200 and the Security locks side 120.

On the 15 December 2000 Gunnebo announced they had carried out a worldwide review of business and decided to cut about 40% of their European safe manufacturing operations. That meant they were closing the Chubb Safe works at Wolverhampton and that 170 jobs would go.

In April 2002 Custodial Services moved to a new, purpose built, factory and offices in Well Lane, Wednesfield. The commercial products continued to be manufactured, along with Union and Yale locks, at Wood Street, Willenhall.

In 2004 Chubb Yale Union opened a new distribution centre on the old Henry Meadows site in Cannock Road, Wolverhampton. When Meadows had closed, Chubbs used part of the site for distribution.

The old Josiah Parkes, Union, and Yale factories in Willenhall are long gone. Assa Abloy is now based in School Street, Willenhall, where high security products including door handles, door locks, access control systems, wireless locking systems, and door closers are produced to this day.

To see more photos from the Chubb collection, click here